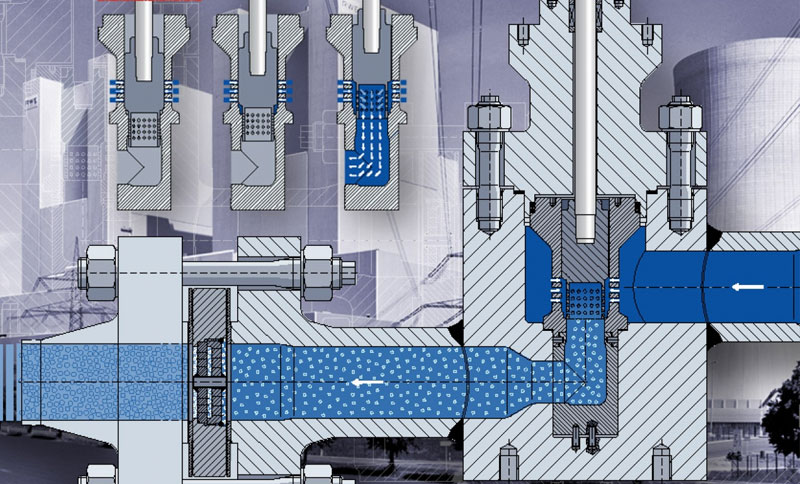

Boiler Feedwater & Steam Systems

Precision Flow Control Under High Pressure & Temperature

Critical for managing water and steam in thermal and nuclear plants

Must withstand superheated steam, thermal cycling, and pressure surges

Supports startup, bypass, and blowdown operations

Ideal Valve Types:

Globe Valves, Gate Valves, Control Valves, Pressure-Seal Valves