Should be performed to verify the thrust required to open, move or close the valve operator at the pressure specified by the Customer in line with project requirements (maximum pressure differential) WEIKIN VALVE has the most modern equipment of Norbar Torque equipment in House to perform such tests till 100.000 Nm

Hydrostatic testing

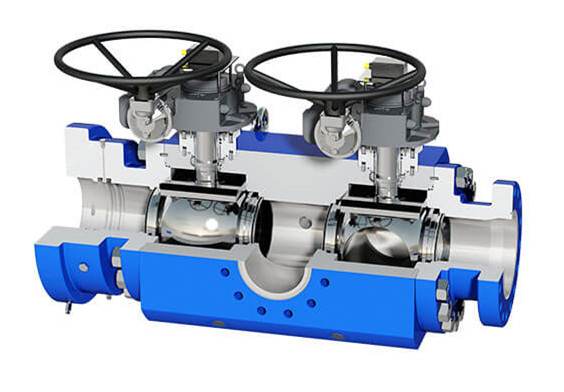

The WEIKIN VALVE Testing Department is equipped with 7 advanced test benches designed for both hydrostatic and gas testing. These facilities can handle valves ranging from ½” to 56” in size, covering pressure classes from CL150 to CL2500, ensuring precise and reliable performance verification under demanding operating conditions.